Discover The Bucket Wheel Excavator: How These Huge Machines Reshape Our World

Have you ever stopped to think about the incredible scale of some machines that work to reshape our planet? It's almost mind-boggling, really. We're talking about devices that move more earth in a single day than many smaller machines could manage in a whole month, or even longer. Among these giants, the bucket wheel excavator stands tall, a true marvel of engineering that helps us get to valuable resources buried deep within the ground. It’s a machine that, in a way, makes the impossible seem possible for big projects, you know?

These massive earth-moving behemoths are not something you typically see on a local construction site. No, they are usually found in very specific, very large-scale operations, like open-pit mines. Their job is to dig up vast amounts of material, sometimes millions of tons each day. This kind of work is pretty important for getting at things we use every single day, from the coal that powers some of our homes to the minerals that go into so many products. So, it really does touch our lives, even if we don't see it directly.

Understanding these machines gives you a whole new appreciation for the sheer effort and ingenuity involved in big industrial tasks. It’s a bit like seeing how a tiny bucket for household chores, perhaps for painting your home or cleaning floors, scales up to something absolutely enormous. While your typical bucket from a place like Lowe's or The Home Depot might be a versatile essential for simplifying tasks around the house, these excavator buckets are built for an entirely different kind of heavy lifting, designed for both incredible strength and capacity. They are, you could say, a different breed altogether.

Table of Contents

- What is a Bucket Wheel Excavator?

- Where Do We See These Giants At Work?

- The Unbelievable Scale of Bucket Wheel Excavators

- The Engineering Behind the Buckets

- The People Behind the Powerhouse

- The Future of Massive Excavation

- Frequently Asked Questions

What is a Bucket Wheel Excavator?

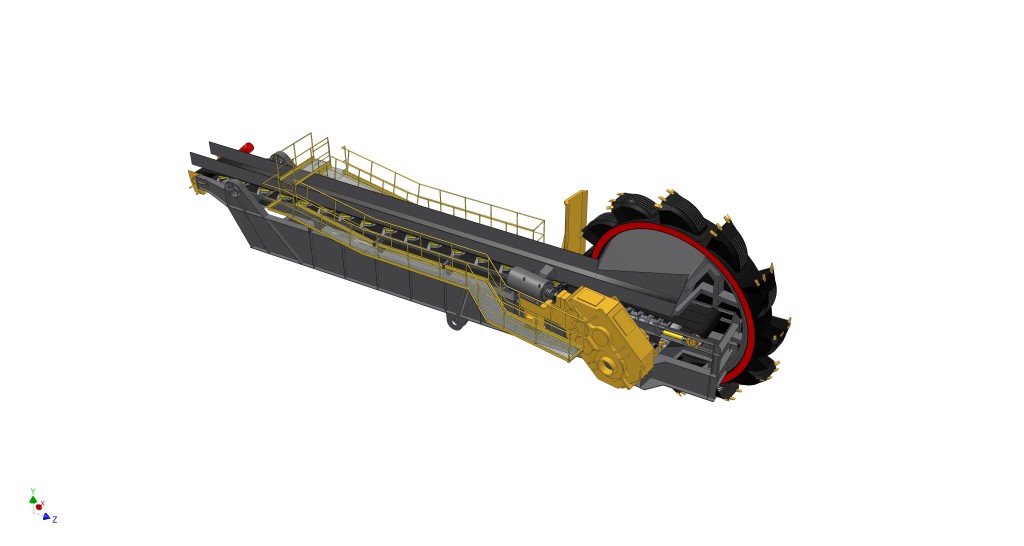

A bucket wheel excavator, often called a BWE, is a continuous digging machine. It's a type of heavy equipment used in surface mining and large civil engineering projects. Think of it as a factory on wheels, moving slowly but constantly, taking huge bites out of the earth. These machines are, like, really something else when you see them in person.

The Core Design

At its heart, a BWE has a massive rotating wheel fitted with numerous digging buckets. This wheel is mounted on a long boom, allowing it to reach far and dig deep. The entire structure sits on a huge crawler track system, letting it move across the landscape. The design, you know, is pretty intricate for such a huge piece of equipment.

The material collected by the buckets gets dropped onto a series of conveyor belts. These belts then transport the material away from the digging face, often directly to another machine or a processing plant. It's a very streamlined process, almost like a giant assembly line for dirt and rock. This setup allows for continuous operation, which is very important for productivity.

How They Operate

Operating a bucket wheel excavator involves a precise dance of movements. The wheel spins, its buckets scooping up earth as it moves along the digging face. As the machine advances, it creates a wide, deep trench. The material then travels along those internal conveyors, perhaps to another giant conveyor system that stretches for miles. This continuous flow is what makes them so efficient, you know, for moving huge volumes.

Unlike smaller excavators that might pick up one scoop at a time, the BWE keeps digging without stopping. This steady, relentless work rate is what sets it apart. It’s a bit like a giant, mechanical river, constantly moving material from one place to another. The sheer amount of earth they can shift is, honestly, just incredible.

Where Do We See These Giants At Work?

You won't find a bucket wheel excavator building your new driveway, that's for sure. These machines are reserved for the biggest jobs, where the sheer volume of material to be moved is staggering. They are, essentially, specialists for truly enormous tasks. So, you'll see them in specific places.

Open-Pit Mining Operations

The most common place to spot a BWE is in large open-pit mines. These mines often extract coal, lignite, or other minerals found close to the surface but spread over vast areas. The BWE strips away the overburden, which is the earth and rock covering the valuable resource. This allows access to the desired material. It's, like, a crucial step in the whole process.

Because they can dig and move so much material so quickly, BWEs are ideal for these kinds of operations where efficiency is key. They help keep the cost of extraction down, which is important for the overall economy of the mine. This is why, in some respects, they are so widely used in these settings.

Large-Scale Earth Moving Projects

Beyond mining, BWEs have also been used in massive civil engineering endeavors. Think about projects that involve creating huge canals, large dams, or leveling vast tracts of land. If you need to move a mountain of dirt, a BWE is one of the tools you might turn to. They are, basically, designed for that kind of scale.

While less common than in mining, their ability to continuously move material makes them a powerful option for certain large-scale construction or land reclamation efforts. It's about finding the right tool for the job, and for truly enormous jobs, these machines are often the answer. They are, in fact, quite unique in their capabilities.

The Unbelievable Scale of Bucket Wheel Excavators

When we talk about "big," we're talking about something truly colossal with these machines. They are among the largest land vehicles ever built, dwarfing almost anything else you can imagine. It's like comparing a small garden bucket to a giant industrial vat; the difference in size is, well, pretty staggering.

Record-Breaking Machines

Some of the largest BWEs, like the Bagger 288 and Bagger 293 in Germany, are simply monumental. These machines can weigh over 13,000 tons and stand taller than many skyscrapers. Their digging wheels alone can be more than 70 feet across, with buckets that could easily hold a small car. It's, you know, a scale that's hard to even picture.

These record-breakers require a crew of many people to operate and maintain them, working around the clock. They are not just machines; they are complex, moving industrial sites. The sheer engineering required to build and move something this huge is, quite frankly, astonishing. They are, literally, mechanical giants.

Moving Mountains, Literally

The capacity of these machines is almost beyond belief. The largest BWEs can move over 240,000 cubic meters of material per day. To give you a sense of that, it's enough to fill about 2,400 railway cars. This means they can, quite literally, reshape the landscape, moving what amounts to small mountains of earth in a matter of days or weeks. This is, in a way, their main purpose.

This immense capacity is what makes them so valuable for continuous mining operations. They keep the flow of material steady, ensuring that the valuable resources can be extracted efficiently. It’s a constant, powerful process that, basically, never stops.

The Engineering Behind the Buckets

The "bucket" in bucket wheel excavator is not just any bucket. These are specialized components designed to withstand extreme forces and abrasion. They are the workhorses of the machine, after all. So, a lot of thought goes into their construction and design.

Materials and Durability

Unlike the plastic buckets you might find at Ace Hardware or the galvanized steel pails from Tractor Supply Co, the buckets on a BWE are constructed of incredibly tough, high-strength steel. This material is chosen for its ability to resist wear and tear from constantly digging through rock, dirt, and other abrasive materials. They need, you know, to be super strong.

The design often includes replaceable teeth and wear plates, which can be swapped out when they get worn down. This extends the life of the main bucket structure and keeps the machine running efficiently. It's about maximizing uptime and minimizing maintenance, which is very important for such a large investment. They are, quite simply, built to last under extreme conditions.

Bucket Design and Function

The shape and size of each bucket on the wheel are carefully engineered for optimal digging and loading. They are designed to scoop up material efficiently and then release it cleanly onto the conveyor system. Different types of materials might require slightly different bucket designs, too. So, there's a bit of customization involved.

The buckets are arranged around the wheel in a way that ensures a continuous flow of material as the wheel rotates. This innovative design, you could say, is key to the BWE's high productivity. It’s a very clever system that, basically, just works tirelessly.

The People Behind the Powerhouse

While these machines are massive and automated in many ways, they still require skilled human operators and support teams. It's not just a matter of pressing a button and letting it go. There's a whole crew involved, you know, making sure everything runs smoothly.

Operating These Huge Machines

Operating a bucket wheel excavator is a highly specialized job. The operator sits in a control cabin, often high above the ground, with a commanding view of the digging area. They control the movement of the entire machine, the rotation of the wheel, and the positioning of the boom. It's a job that demands a lot of focus and precision. They are, arguably, the conductors of this giant orchestra of steel.

Beyond the primary operator, there are teams of engineers, technicians, and maintenance personnel who keep the BWE running. They perform regular checks, troubleshoot issues, and carry out repairs. It's a continuous effort to ensure the machine stays productive and safe. This collaborative effort is, like, pretty vital for success.

Safety and Precision

Given the sheer size and power of these machines, safety is paramount. Strict protocols are in place to protect the operators and anyone working near the BWE. Every movement is carefully planned and executed to avoid accidents. This is, very, very important for everyone involved.

Precision is also key. The operators must guide the BWE to dig exactly where needed, following the contours of the mine or the project plan. This ensures efficient material extraction and proper shaping of the land. It’s a delicate balance of power and accuracy, you know, that really defines the work.

The Future of Massive Excavation

The world of heavy machinery is always changing, and bucket wheel excavators are no exception. There's a constant push for improvements, whether it's making them more efficient or finding ways to reduce their environmental footprint. It's a field that, honestly, just keeps evolving.

Innovation and Efficiency

Engineers are always looking for ways to make BWEs even more productive and less resource-intensive. This includes advancements in automation, better materials for components, and more energy-efficient drive systems. The goal is to get more done with less impact, which is a pretty good aim. They are, in fact, always trying to refine these giants.

New designs might also focus on making these machines more adaptable to different types of terrain or materials. As technology improves, we might see BWEs that are even smarter and more responsive to changing conditions. It’s about pushing the boundaries of what these amazing machines can do, you know?

Environmental Considerations

With growing awareness of environmental impacts, the operation of BWEs is also evolving. Efforts are being made to reduce dust emissions, manage water usage, and reclaim mined land more effectively. The aim is to balance the need for resources with responsible environmental stewardship. This is, you know, a big part of the conversation these days.

There's also interest in exploring alternative power sources for these massive machines, moving away from fossil fuels where possible. This could involve electric drives powered by renewable energy or other cleaner technologies. It's a big challenge, but one that's getting a lot of attention, which is, honestly, a good thing for everyone.

Frequently Asked Questions

People often have questions about these enormous machines. Here are some common ones:

How big is the largest bucket wheel excavator?

The largest bucket wheel excavators, like the Bagger 293, are truly immense. They can stand over 310 feet (95 meters) tall and stretch for over 720 feet (220 meters) long. They weigh more than 14,200 tons. It’s, like, a truly astonishing size, bigger than many buildings.

What materials can a bucket wheel excavator dig?

Bucket wheel excavators are primarily designed for digging soft to medium-hard materials. This includes things like coal, lignite, sand, gravel, and various types of overburden (the soil and rock above a mineral deposit). They are not typically used for very hard rock excavation. So, it's more about volume than extreme hardness.

How many people does it take to operate a bucket wheel excavator?

While one main operator controls the machine from the cabin, a full crew is needed to keep a bucket wheel excavator running. This includes additional operators for support equipment, maintenance teams, engineers, and supervisors. A large BWE operation might involve dozens of people working together in shifts. It's, basically, a team effort.

We hope this glimpse into the world of the bucket wheel excavator has been interesting. It's a powerful reminder of human ingenuity and the incredible machines we create to tackle the biggest challenges. Learn more about heavy machinery on our site, and perhaps discover other amazing machines on this page . These machines truly reshape our world, every single day.

Bucket Wheel Excavator Mining Surface - MCI Mining Construction Int.

KR4500Nk – BUCKET WHEEL EXCAVATOR (K 1100) - NOEN, a.s. | NOEN, a.s.

KR1300Xk – BUCKET WHEEL EXCAVATOR (K 400) - NOEN, a.s. | NOEN, a.s.